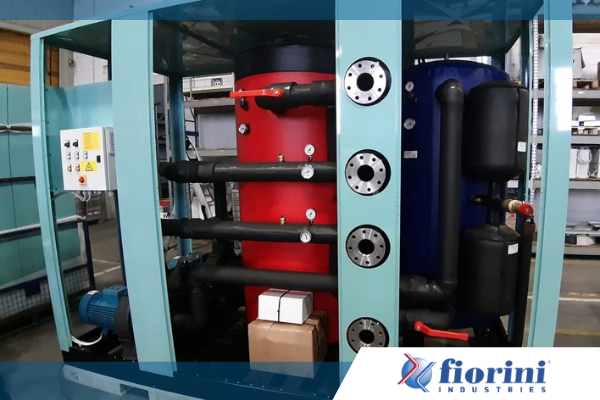

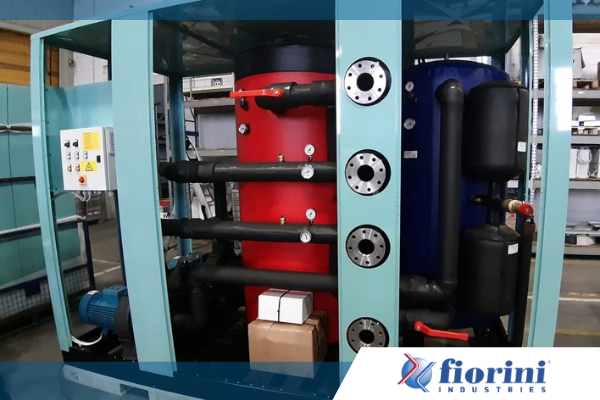

CASE HISTORY: Fiorini customises its HPT unit and doubles its functions: hot/cold in a single hydronic kit.

Published in 11/02/2021

Fiorini has created the hydronic component of a system designed for a milk processing plant, which the aim to allow for the efficient management of two separate functions: the cooling of the cells used to store cheese and the production of the heat required to defrost the coils.

The challenge? To meet the needs of a customer, who required a single hydronic kit with a double hot/cold function instead of two separate HPT units, which is the standard solution for this type of situation.

The Fiorini team therefore got down to work to install a double tank and a double pump unit on the frame of the standard hydronic kit, usually configured for a single horizontal tank. The independent management of the two pump units was entrusted to an intuitive and easily accessible electrical panel, the necessary safety devices were included and, to complete the kit, a tailored box was made for outdoor installation.

The design work had to take into account various factors, such as the calculation of the powers involved, the consequent storage volume, the size of the pumps and, finally, the ratio between the overall volume and the available space, both “on site” and on the vehicle that would take it to destination.

The solution was the hydronic kit, which, thanks to significant customisations, has made it possible to facilitate system installation operations and to meet specific needs related to the installation context.

The perfect synthesis of benefits of a pre-assembled HPT unit and the uniqueness of a tailored product.