HP 2.0

Published in 02/05/2018

HP 2.0 HYDRONIC KITS

Hydronic system

HP 2.0 units are hydraulic stations designed to reduce the set-up times of conditioning systems and cooling systems. They can be combined with any type of water cooler.

The wide choice of pump combinations can meet the design needs of any system.

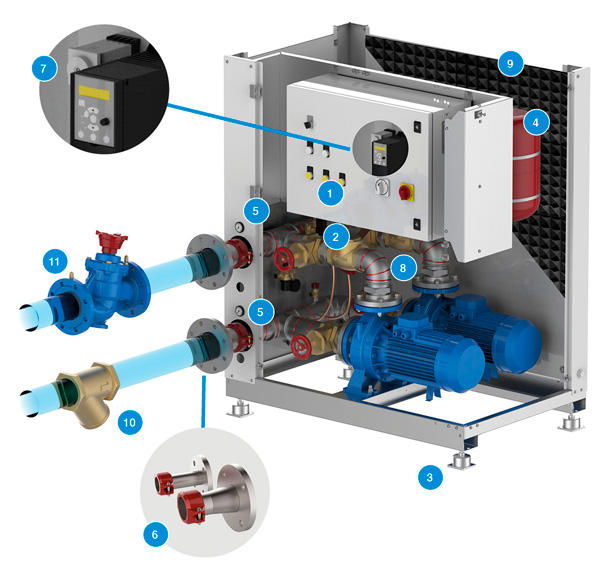

HP 2.0 hydronic kits come with piping insulated with closed cell elastomeric insulation, single or double centrifugal pump with shut-off valve, power switchboard, safety valve, deaerator, manometer, expansion vessel available on request.

Standard HP units follow the hydronic chart for hydronic kit, chiller and system connected in series, thereby obtaining a constant water flow throughout the entire system.

FEATURES

Flow range

From 1 to 320 m3/h

Pump control version

ON/OFF or Inverter

Standard version

Single or Double Pump

Power supply

Three-phase 400 Volt

Storage tank arrangement

Vertical/Horizontal

Installation

Outdoor/Indoor

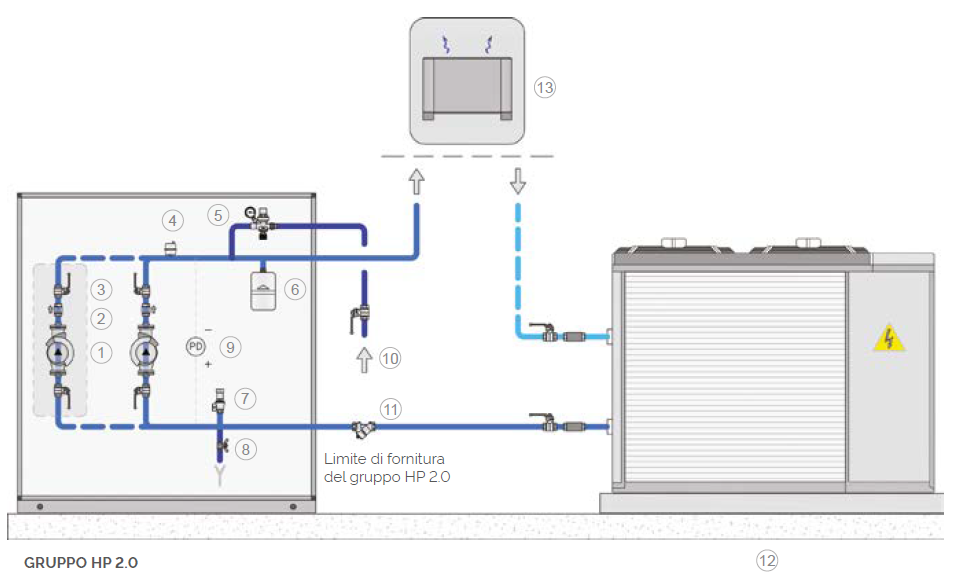

LAYOUT STANDARD

Hydronic kit, chiller and plant connected in series, hence the water flow is constant throughout the plant.

ACCESSORIES

For the HP 2.0 hydraulic stations, Fiorini has a set of accessories, both standard and on request, available to the customer. These accessories are indispensable in offering quality products that can meet all the customer’s needs.

| Accessory type | Descrizione | Esecuzione |

|---|---|---|

| 1 Alternating pump timer | Gestione alternanza pompe a intervalli di tempo determinati nelle configurazioni con doppia pompa. | Standard |

| 2 Differential pressure switch | Dispositivo di sicurezza per la verifica del flusso. | Standard |

| 3 Anti-vibrating feet | Collocati nei punti d'appoggio della macchina attenuano le vibrazioni. | Standard |

| 4 Expansion vessel | Il kit viene fornito assemblato e montato all'interno della macchina. | Standard |

| 5 Manometer kit | Il kit montato nella carpenteria da la possibilità di monitorare la pressione del circuito. | Standard |

| 6 Flanged connections | Trasformano le connessioni victaulic di serie in connessioni flangiate. | Standard |

| 7 Inverter | Gestione della pompa tramite inverter con sensore 0-10 bar e segnale 4-20 mA. | A richiesta |

| 8 Antifreeze electric resistor | Il kit prevede una protezione contro il congelamento mediate cavo scaldante avvolto attorno alle tubazioni. | A richiesta |

| 9 Soundproof coating | Insonorizza la carpenteria attenuando il livello di emissioni sonore. | A richiesta |

| 10 Filter | Filtro da 1000 micron per proteggere le pompe da eventuali impurità. | A richiesta |

| 11 Balancing valves | Sopperiscono al bilanciamento del circuito. | A richiesta |